The National Landmarks Wincell Insulation used in those years

2020-01-30

The National Landmarks Wincell Insulation used in those Years

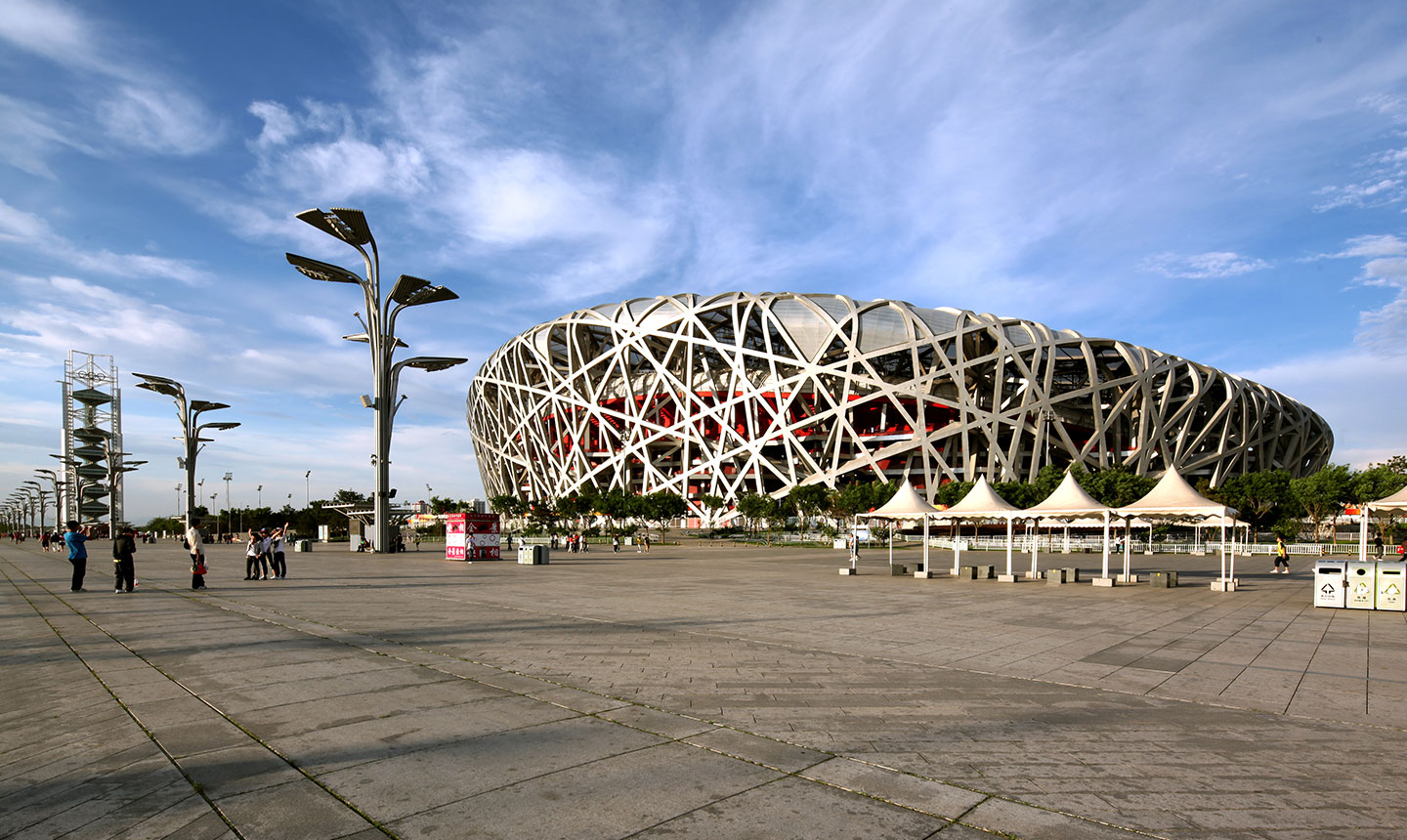

As the 2016 Rio Olympics draw near, many Chinese are thinking back to the 2008 Beijing Olympics. The success of the Beijing Olympic Games attracted the world's attention, and left the world still breathtaking national aquatics center (Water Cube), National Stadium (Bird's nest) and other Olympic landmarks. In order to meet the theme of "green Olympics", a large number of building energy saving products have been adopted in the Olympic buildings, among which we win the rubber and plastic figure.

The national stadium (bird's nest) is the main stadium for the 2008 Beijing Olympic Games. The project covers a total area of 21 hectares. Construction started on December 24, 2003 and was completed in March 2008, with a total cost of 2.267 billion yuan. As a national landmark building, the main structure is designed to have a service life of 100 years, and the fire resistance grade is 1, the seismic fortification intensity is 8, and the underground engineering waterproof grade is 1. Bird's nest air conditioning cooling pipe material USES Wincell rubber insulation material 1800 cubic meters.

In addition to the bird's nest, Wincell's rubber insulation products are used in the national grand theater, the office buildings of the National People's Congress, wanda plaza and other state key projects and large buildings. Among them, take the scale of wanda plaza project as an example. Currently, Wincell has participated in the supply of rubber and plastic insulation materials for more than 80 wanda commercial real estate projects. Up to now, there are more than 30000m3 of rubber and plastic insulation materials, which are applied in air and water pipe insulation of central air-conditioning hvac system.

Wincell is also involved in tens of thousands of engineering projects. Such as: Shanghai World Expo, Nanjing Youth Olympic Games, Capital Airport, Greenland Group, Samsung Electronics, Huawei technologies, Beijing-Shanghai high-speed railway nanjing south station, aircraft carrier liaoning and other national key projects.

In addition to Wincell selected for national key engineering projects, the three global air conditioning giants york, traning and McVail also jointly choose Wincell rubber insulation materials. Wincell rubber is the supplier of traning, york and McVail.

In order to get rid of the old and bring out the new, Wincell company also launched a series of high-performance composite products, the appearance is no longer confined to the traditional dark color system, widely used in the room pipe insulation and plant air supply pipe insulation, let the customer's air-conditioning system shine.

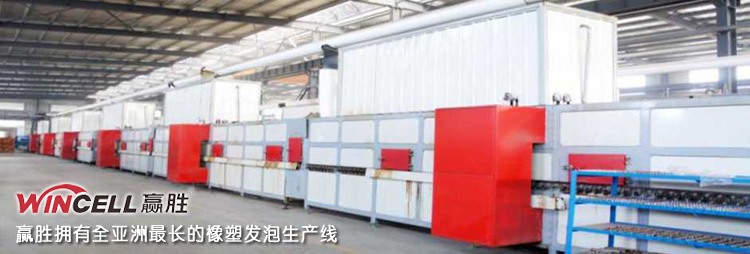

Wincell Insulation Co.,Ltd. Is a large rubber Insulation material manufacturer with internationally advanced equipment and production scale. Jiangsu taixing production base covers an area of more than 900 mu. The 170m-long foaming path in the rubber and plastic insulation pipe production workshop ensures that the rubber and plastic foam is more sufficient, the foam hole is more uniform, and the insulation effect is better. The company has passed the American FM certification, the United States GREENGUARD green certification, the United Kingdom BS certification, the United States UL certification, ISO9001 system certification, Korea KS certification, China CQC certification and the European Union CE certification.

Each Wincell rubber and plastic product is refined through "triple refining technology", "six-level gel foaming technology" and "12-hole precision extrusion technology".

3. Secondary refining technology:

In order to ensure the production of high quality rubber and plastic insulation materials, the refining process of yingsheng is increased from 2 to 3, realizing the 3 refining technology of "1 heavy refining and 2 heavy refining" (common brand rubber and plastic only 1 heavy refining), so as to achieve perfect uniform integration of the formula.

Level 6 gel foaming technology:

Wincell adopts the third generation of "gel foaming" technology, with smaller bubbles and better weather resistance. The gel foaming production line is 170 meters long, which is about 3 times of that of ordinary manufacturers. It adopts the mode of "slow simmering" and even heating, which makes the foaming more uniform, higher bubble closure rate, more foam holes per unit area, about 4-10 times of the number of rubber and plastic foam holes, better compression resilience and better insulation performance.

12 hole fine control extrusion technology:

Wincell introduces the high-end 12-hole precision extrusion mold, which ensures more stable equipment performance, higher extrusion accuracy and uniform wall thickness of pipes of the same model. At the same time, production efficiency has been greatly improved, energy consumption per unit of production has been greatly reduced, and energy conservation and environmental protection have been enhanced.

Currently, Wincell insulation products are exported to Europe, the americas, the Middle East and the asia-pacific region, and are widely used in various industries around the world, such as real estate, electronics, automotive, tobacco, medical care, food, supermarket, finance, transportation and other industries.

Wincell Insulation Co., Ltd., from jiangsu China brand of high-end thermal Insulation material, has been based on the Chinese market, with globalization, to further expand the adiabatic markets around the world, to the superior performance of rubber and plastic products, Insulation can meet the needs of all over the world every special requirement of working environment and the general living environment and create a more comfortable and energy saving space.